FAQ

Are Angular Momentum Watches better than other brands?

Determining whether Angular Momentum watches are "better" than other brands depends on various factors, including craftsmanship, design, uniqueness, and personal preference. Here’s a comparative analysis to help you understand where Angular Momentum stands:

1. Craftsmanship

- Angular Momentum: Each watch is meticulously handcrafted, focusing on artisanal techniques and high-quality materials. The brand often employs traditional methods like Urushi lacquer and Verre Églomisé, resulting in timepieces that are both functional and artistic.

- Other Brands: Many luxury watch brands (like Rolex, Patek Philippe, or Audemars Piguet) also emphasize high craftsmanship, often using advanced technology alongside traditional methods. However, they may not incorporate the same level of unique artistic techniques as Angular Momentum.

2. Artistic Design

- Angular Momentum: Known for its innovative and artistic designs, Angular Momentum watches are often considered wearable art. The use of unconventional dials and creative aesthetics sets them apart in the luxury watch market.

- Other Brands: While many brands offer beautifully designed watches, they may follow more traditional styles and conventions. Brands like Jaeger-LeCoultre or IWC are renowned for their classic designs but may not push the envelope in the same way Angular Momentum does.

3. Exclusivity and Rarity

- Angular Momentum: Produces watches in very limited quantities, enhancing their exclusivity. Many pieces are custom-made, which adds a personal touch and rarity to each watch.

- Other Brands: While many luxury brands produce limited editions, they often have a broader distribution. Brands like Omega or Tag Heuer have more widely available models, making them less exclusive than Angular Momentum.

4. Customization

- Angular Momentum: Offers bespoke services that allow customers to work closely with the designer to create a unique timepiece tailored to their preferences. This high level of customization is rare in the luxury watch market.

- Other Brands: Some luxury brands offer customization, but it often has limitations. Brands like Rolex and Breitling have set models, while bespoke options are less common.

5. Price and Value

- Angular Momentum: While they may be less known than some larger luxury brands, the price reflects the artistry and craftsmanship involved in creating each piece. They are often considered a good value for collectors seeking unique, high-quality timepieces.

- Other Brands: Established brands like Patek Philippe and Audemars Piguet command high prices, often more for brand prestige than artistic individuality. Depending on the market, some may appreciate more over time compared to Angular Momentum.

6. Functionality and Performance

- Angular Momentum: Focuses on aesthetics and artistic expression, and while their movements are reliable, they might not always match the technical prowess of brands that prioritize functionality (like Seiko or TAG Heuer).

- Other Brands: Brands like Rolex or Tag Heuer are known for their robust and reliable movements. If performance is a key factor, these brands may be more suitable.

7. Personal Preference

- Ultimately, the choice between Angular Momentum and other brands comes down to personal taste. If you value artistic expression, exclusivity, and handcrafted quality, Angular Momentum stands out. However, if you prefer robust functionality, traditional designs, or brand prestige, other brands may align better with your preferences.

Conclusion

Angular Momentum watches offer a unique blend of artistry, craftsmanship, and exclusivity that appeals to collectors and enthusiasts of wearable art. While they may not be "better" in a traditional sense—particularly regarding mass-market recognition or robust performance—they excel in areas that are highly valued in the niche of artisanal luxury watches. Each brand has its strengths, so the best choice will depend on what you personally prioritize in a timepiece.

Meaning of Angular Momentum?

ANGULAR MOMENTUM is a concept taken from astrophysics that derives from the combination of a moment of inertia with an angular velocity. The term dates back to the German astronomer and physicist JOHANNES KEPLER (*1571) and means the TORCH. The term Angular Momentum is also used in movement making and describes the force of a movement.

Revolving-Disk-System (R.D.S.)

There have been repeated attempts to revolutionize the proven two-hand time display system with new innovations. The patent for the disc system (R.D.S.) is an alternative time display system without traditional hour, minute and second hands. but with discs that allow almost infinite options of watch face designs. Since the discs - depending on size and weight - are between 100 to 500 times heavier than traditional hands, watches with discs should considerd not be worn during sports such as golf, tennis martial arts, etc.

Movements - Golden Age Calibers

Historically, the Swiss watch and clock industry has always had a specialized horizontal structure in which suppliers, craftsmen and sub-contractors supply movements and external parts to assemblers called "établisseurs", who put the final product together. However, to a lesser extent, the industry has also developed a vertically integrated structure in which watches and clocks are sometimes made entirely by the same company, in this case called a "manufacture".

Angular Momentum is considered not a manufacturer of so called "complicated watches"

Our Artisan Timepieces are all fit with historical (NOS) new-old-stock movements manufactured between 1950 to 1975 by FHF (Fabrique d'Horlogerie Fontainemelon) and AS (Adolf Schild SA) and Unitas SA which became the today's ETA SA later on.

The FHF and AS movements are - though 50 to 70 years old - of excellent quality. Some say even better than today's mass produced movements. All movements have never been used before and are completely overworked, decorated and if necessary modified in the Angular Momentum ateliers in Bern.

The movements I use in myy watches have been supplied by FHF and AS between 1910 and 1980 in large quantities to well known brands among them:

Tissot Cal. 2132/35/36/37 = FHF 69N, Bulova Cal. 3AL = FHF 59, Cortebert Cal. 732 = FHF 73-4, Doxa, Dugena Cal. 3605 = FHF 96, Dugena Cal. 677 and 777 = FHF 70, Elgin = FHF 905, Gruen Cal. 220 = FHF 60, Longines Cal. 510 = FHF 59-21, Lucien Paccard, Sefes, Silvana, Tudor Cal. 390 = FHF 96, Waltham Cal. 1155 = FHF 70, Zodiac Cal. 58 = FHF 81 (1965) and FHF 96, FHF Auto 909, Eaton Solar Aqua movements = FHF, Girard Prregaux Cal. GP 86 = FHF (1930-60), Girrard Perregaux Cal. GP 21 Gyromatic = FHF 90-5, Girrard Perregaux Cal. GP 461 = FHF 90-5905, Alpina Cal. 647 = FHF 70, Alpina Cal. 668 = FHF 28, Alpina Cal. 821 = FHF 123, Rolex Cal. 59 (CS) = FHF 30-1 (around 1945), Rolex Cal. Marconi special and Rolex Viceroy (from 1919) = FHF.

.jpg)

Stainless steel

Angular Momentum & Manu Propria exceptionally uses 1.4435Ncu "Staybrite" steel for its stainless steel watch cases and fittings.

Staybrite® 4435NCu is a patented, austenitic chrome-nickel-molybdenum steel that has been further developed on the basis of the tried and trusted Staybrite® 4435 by Hempel Special Metals AG. The requirements on watch steel, in particular the ability to polish large area cases, have grown significantly over the past years. Hempel Special Metals AG thus decided a few years ago to develop a new material on the basis of the tried and trusted watch steel Staybrite® 4435. This new steel, Staybrite® 4435NCu, differs even more distinctively from the 316L (1.4404) used in the Far East because it is easier to polish, has a better resistance to corrosion and better tolerance working properties. This new watch steel has been approved by Swiss watchmakers having successfully passed their stringent tests. But due to its higher price, only few watch companies, such as Angular Momentum & Manu Propria are using this very special steel.

.jpg)

Movement Régulateur

July 2012, Angular Momentum has introduced its in-house "Régulateur" movement.

The main plate and extensions are completely made in the atelier by hand and with hand operated machines. No CNC machines are involved in the manufacturing process.

(1).jpg)

Date Setting

Self-winding and hand-winding movements with date display are fit with an instantaneous date, date corrector, which is operated over the winding stem 2nd position. It is not recommended to set the date by date corrector between 21.00H and 03.00H. Some manufacturer recommend to set hands to (local time) 06.00H before setting the date because of frictions of the date indicator driving wheel. The date changing process lasts around 3 to 4 hours, depending to the movement construction and starts whit the indicator driving wheel touching the date disk.

To prevent of any frictions which leads to a repair at the manufacturer, Angular Momentum's watches with date display are assembled, that the date changes in the early morning hours between 07.00H and 08.00H

.jpg)

Verre Églomisé - Miniature Painting

Reverse painting on glass - Églomisé

Reverse painting-on-glass is a uniquely difficult and skillful art.

This reverse painting, as églomisé is known in English, which is done here backwards on the inside of the sapphire crystal, is a unique, rare, and difficult art that is brand-new to the horological scene.

What makes this particular technique so difficult is the sequence of paint application necessary to achieve it successfully. The resulting painting is actually seen in reverse from the front, so the paint must be applied opposite to the intended effect, requiring a great deal of imagination, patience, and skill – most especially when the painting involves an entire palette of colors, as Angular Momentum’s certainly do.

Preparation of Sapphire Glass

Before a sapphire crystal can be painted, the surface has to be cleaned, by keeping it in hot concentrated Hydrochloric acid to remove all metallic remains and in a 250°C hot oven over night to remove organic remains.

Painting Procedure "Floating Pigments"

On the reverse of the sapphire crystal or dial, the painting is applied by using Aqua Regia oil and color pigments, a minute and painstaking work and procedure putting layer on layer with brushes and fine needles.

As a final step three protective layer of Japan Urushi laquer is applied over the miniature at the reverse of the sapphire dial or crystal.

.jpg)

The advantage of Verre Églomisé compared to normal miniature painting?

The technique of Verre ÉglomisÉ miniature painting on the reverse of saphire watch crystals has been developed by Martin Pauli in 2004. The technique bases on Aqua Regia oil and pure color pigments. Differently than regular miniature paintings on mother of pearl or enamel, Verre Églomisé miniatures are not damaged, when water gets into the timepiece. The miniatures made by Martin Pauli are considered some of the finest available on the market today. The main advantage but is, that there are no watch hands disturbing the miniature picture. Angular Momentum's Verre Églomisé timepieces show the time digitally through an apperture, by an hour disk à "Souscription" with hour, quarter hour and 5-minute indexes.

.jpg)

Pad Print

Angular Momentum uses a historic pad printing machine for printing numerals and indexes on dials and of coarse on revolving hour-disks à "Souscription"

.jpg)

.jpg)

Urushi - Japan lacquer

The first timepieces with Japan lacquer dials have been made in 2004. Several traditional Japanese Urushi lacquer techniques have been executed. Low and high relief "hiramaki" and "takamaki", black on black "yamimaki", carving "tsuishu" and "chinkin", mixed inlay techniques "tsugaru nuri" and many more.

The process of Urushi is a very skillfull and time consuming craft. Urushi is very robust. An urushi-coated bowl for example can withstand the extreme temperatures of being used for hot soup every day. Its chemical resistance is also so high that even aqua regalis (nitrohydrochloric acid) which melts gold cannot erode it. Urushi has a hardness of 6 on the Mohs scale

more information: http://www.youtube.com/user/fushimiurushikobo

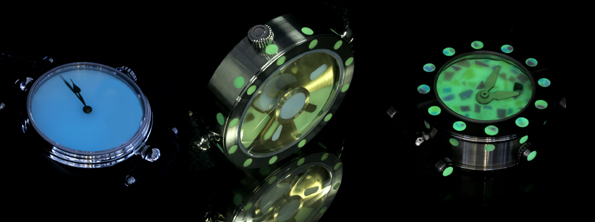

Glowing Urushi

Glowing Urushi has been recently developed by Angular Momentum.

Its a mixture of high quality and very transparent Japanese Urushi lacquer, Titanium white and a specialy prepared powder made of Oyster shell and other incrediences..

The Glowing Urushi is proceeded as normal lacquer, applied with a brush layer by layer - of coarse after every layer has been properly hardened in the "Furô" for 24 hours.

.jpg)

Email Lumineuse

The Èmail Lumineuse is a recent development of Angular Momentum after a historic receipt, a fusion of enamel and a non-radioactive substance which is in the position to glow for many hours after being loaded under artificial or sun light for a period of time. The Èmail Lumineuse is only available in "Aqua Blue" and "Pale Green". Since it is an organic product, minor irregularities in the enameled areas must be accepted.

Luminous Enamel (Receipt)

Five parts of the ordinary luminous powder prepared from oyster-shells; ten of fluor-spar, cryolite, or other similar fluoride; one of barium borate; powdered, mixed, made into a cream with water, painted on the glass or stone article, dried, and fired in the usual way for enamels. If the article contains an oxide of iron, lead, or other metal, it must be first glazed with ground felspar, silica, lime phosphate, or clay, to keep the sulphur of the sulphide from combining with the metal. The result is an enameled luminous article.

When was the R.D.S. Technology invented?

In 1998 the Swiss patent CH 686988 was given for the Revolving-Disk-System.

Watch Cases

All watch parts, cases, crowns, hands, artworks are executed in the ateliers by hand and hand operated machines. Angular Momentum only works with external specialists for complicated diamond setting and very difficult guilloche works.

.jpg)

Sparkling Timepieces

The Sparkling Timepieces are all fit with a 3.00 mm thick sapphire crystal on which's back side in a first step an aperture in Gold or steel is fixed. In a second step brilliant cut diamonds of various size are fixed. In a third step, diamond dust and splitters are distributed evenly on the crystal. After the fixing material has dried, black enamel is applied over the entire decoration and the cristal is fired in a furnace

.jpg)

Movement Restoration

Angular Momentum restores respectively overwork old movements. All new old stock movements used in our watches are ebauch or pre-ebauche movements, completely cleaned, oiled, assembled and tested in our atelier.

On demand and for bespoke timepieces also special movements are purchased and restored in our atelier.

.jpg)

.jpg)

Bronze Watch Cases

Already in 2009, we have made watches with cases of bronze for which we used Aluminum-Bronze, an alloy as hard as stainless steel. We have made very classic watch cases but also very sporty ones.

more information: http://www.angularmomentum.com/e/collection.e/watch_detail.e.jsp?ID_Display=1000IR&ID_ProductgroupDisplay=100000

Zirconium Metal

In 2012, Angular Momentum has manufactured its first timepiece completely made of Zirconium metal, probably the first timepiece ever made of this exclusive material.

Zirconium Zr 702 has high affinity to oxygen that facilitates the formation of a protective oxide film which result a high corrosion resistant in the most acids. Zirconium is used in various applications in the nuclear industry. Furthermore in the chemical industry for valves, pumps, tubes and heat exchanger as well in the medical industry for the reason that zirconium is biocompatible and non-toxic. Zirconium has the fourth lowest electronegativity, It‘s hardness (Mohs 5) is slightly below stainless steel.

.jpg)

more information: http://www.angularmomentum.com/e/collection.e/collection_detail.e.jsp?ID_Display=10001X&ID_ProductgroupDisplay=100000

Sculpture Collection Construction

The construction of our Sculpture Timepieces are as following. The case body is sculptured in wax, then cast in Silver or Gold and finally overworked by hand, engraving polishing and milling of the inner dimensions.The movement, movement holder and dial is usually kept in a stainless steel container and set into the sculpture case. But depending to the complexity of the sculpture, some are constructed without container.

Diamond setting

Angular Momentum works with only the best Top Wesselton VVS diamonds and gemstones, supplied by reliable suppliers in Switzerland. Diamonds setting is a very fastiuous work and not executed in our ateliers. For setting of stones we work with the best stone setters in Switzerland.

.jpg)

Engraving, Repoussé, Uchi-Dachi

All metal works are executed in our ateliers. Angular Momentum uses many different techniques such as classic Engraving, Repoussé, Chasing and Uchi-Dachi a distinctly Japanese process that blurs the distinctions between what is commonly known as Metal "sinking" and metal "raising".

.jpg)

Shibuichi and Shakudo

Shibuichi is a Japanese term for an alloy of silver and copper, literally: "shi" = four, "bu" = part, "ichi" = one.

The classic mixture is 5 to 25% silver and the rest pure copper. The more slver the alloy contains, the lighter the color and the harder the material. Shibuichi can be treated as any precious metal, being cast and engraved. After poishing process, the Shibuichi is patinated with "rokushô" a liquid made of organic ingediences among them horse raddish. Depenbnding to the silver-copper mixture, colors are achieved between pinkiesh pearl gray and dark gray.In our ateliers, we make our own Shibuichi alloy in various mixtures for making watch cases and dials.

We also use another Japanese alloy called "Shakudo", an alloy of copper and 3 to 5% gold. This material can be colored with "rokusho" as well. The favoured color is a dark purplish eggplant color or so called "Cormorand feather color"

Does Angular Momentum still produce the PIONEERS R.D.S. Collection?

The four models of the PIONEERS Collection where limited on only a few thousand pieces.

The production was in 1998 and all watches of this line have been sold out.

.jpg)

When was Angular Momentum founded?

Angular Momentum trade Mark has been registered in 1999.

Design Development

CAD changed the face of engineering, of course. But not only we have complaints. Chief among the complaints: CAD allows the user to do things that are hardly possible to do in the real world except with complicated CNC machines. Less experienced engineers can overlook this important fact and create more work for everyone down the line. Novices also tend to fall into habits that are easy for them, allowing CAD to constrain them.

Because of CAD most products look same and its hard to find products, which look unique and different. The designs of Angular Momentum watches are all developed in house by hand sketches and drawings. We don't work with CAD programs.

.jpg)

International Warrantee

ANGULAR MOMENTUM LIMITED INTERNATIONAL WARRANTY.

Angular Momentum Timepieces are in general understood as «Unique Pieces» manufactured on demand.

Your Angular Momentum watch is made and tested to ensure it work. Under our Limited International Warranty, Angular Momentum agrees to correct, free of charge, any problems affecting the functions of your watch that are due to a manufacturing defect. The Limited International Warranty against manufacturing defects for a period of twenty-four (24) months from the date of purchase covered

What is not covered by the International Service Guarantee?

The International Service Guarantee is not a service contract.

The following damages are excluded from the warranty:

(a) Defects or damage caused by loss, theft or fire;

(b) Defects or damage caused by misuse or negligence, or resulting from an accident;

(c) defects or damage caused by improper use like swimming, diving. Tennis, Golf, Martial Arts and such (blows, impacts or other effects on the glass, bracelet, etc.), by interventions of third parties

(d) consequences of normal wear and tear and aging;

(e) routine maintenance and cleaning.

Water Resistance

Please note, that Angular Momentum watches are made to order and are to be understood as unique pieces, some of them working prototypes. Angular Momentum Timepieces generally do not belong in water unless a specific pressure or water resistance is explicitly specified.

Down load the pdf on Water Resistance

more information: https://www.angularmomentum.com/angularmomentum-webseite2/uploadfiles/static/8e6a37e/f4184e3d-7b5e-43a5-9772-bc31c0f17d2c.pdf/On%20Water%20Resistance.pdf